Usage Tips

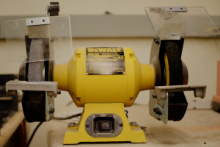

Bench grinders feature abrasive wheels suited to many tasks related to metal fabrication. These tasks include, but are not limited to:

- Rough Shaping

- Polishing

- Sharpening

An important note about the abrasives used with bench griders is that they are specifically designed to be used with metal. Using wood or acrylic on a bench grinder will quickly ruin the wheel and require an expensive replacement. Aside from that, usage is fairly similar to that of a belt sander.

The best practice for the grinder is to identify the task you wish to complete and whether the grinder is both suited for the task and is equipped with the proper wheel to complete said task (the Prototyping Lab team can help with this!), and then to slowly work your material. Working slowly reduces the chance of sparks flying while giving you the opportunity to check the state of your material to ensure you don't accidentally grind it down too far!

Please note: you should always be aware of the safety considerations, like the ones listed below, for any tool you use. Additionally, these tips do not serve as a replacement for proper training. If you're unfamiliar with the operation of a tool, please ask a team member for help and guidance to guarantee the success of your project and the safety of everyone in the lab.

- The bench grinder features a high-speed, rotating abrasive. As such, be very careful during operation and ensure it is off whenever you are not using the tool.

- As this tool is used to grind metal, sparks may be generated during operation. Please ensure the guards on the machine are in place and eye protection is worn during use of the tool.

- Any rotating object can catch on loose materials like sleeves, hair, or gloves. It is particularly common to forget to remove gloves while using this tool, which can result in a very serious injury known as an avulsion, or degloving. Please ensure you remove gloves and any loose jewlery, and you secure any loose clothing/hair prior to use.